-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

TDP16035002AUF Repair & Testing Guide for 50K Thin-Film

Many technicians encounter inconsistent resistance, element opens, or temperature drift when servicing 50K thin-film resistor networks; these symptoms waste bench time and risk product failure. This guide presents a concise repair and testing workflow for TDP16035002AUF, covering rapid triage, precision testing, and field rework techniques. It emphasizes repeatable pass/fail criteria, required tools, and failure signatures so bench engineers can speed diagnosis and reduce returns.

Point: Begin with a structured testing plan. Evidence: A staged approach—visual, low-power screening, then precision tests—catches most faults without introducing stress. Explanation: Following the sequence reduces risk to remaining elements and provides data for repair-versus-replace decisions during thin-film resistor testing.

1 — Background & Key Specifications (background introduction)

1.1 Core electrical specs to know

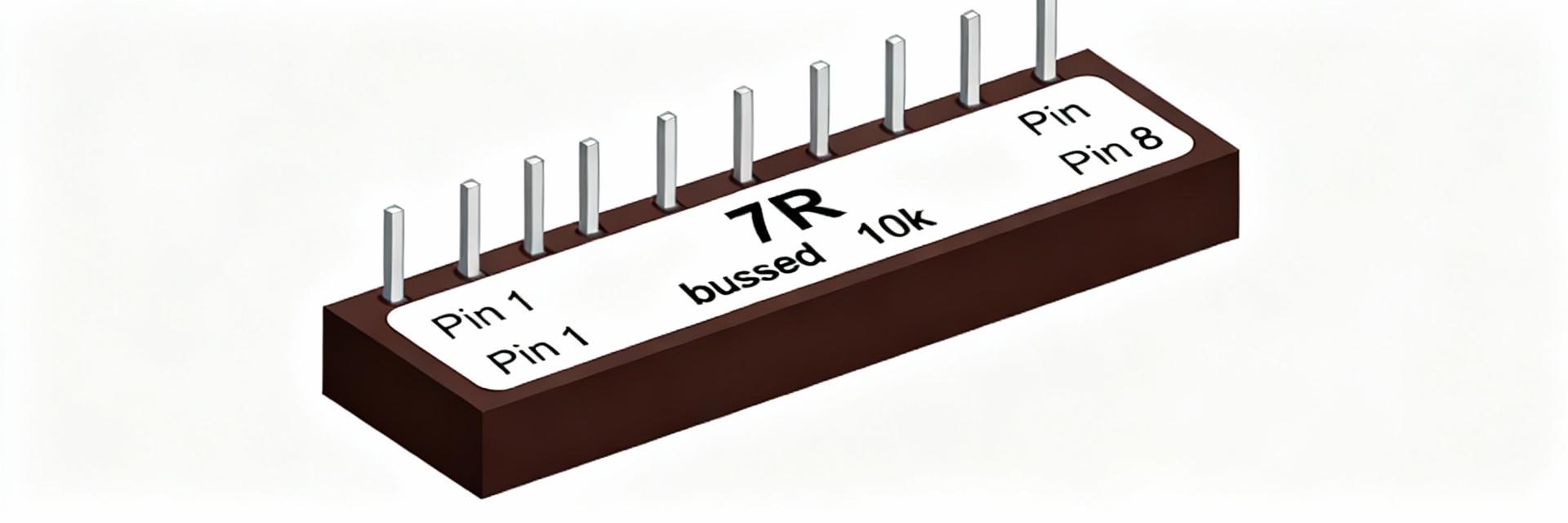

Point: Know the element baseline. Evidence: Each element is 50 kΩ with specified tolerance and TCR in ppm/°C, an element power rating, element count and isolated circuit topology in a 16‑pin DIP through‑hole package with defined operating temperatures. Explanation: Resistance, tolerance and TCR determine pass/fail windows and influence temperature‑based testing protocols and power stress limits.

1.2 Why thin-film networks fail differently than discrete resistors

Point: Failure modes differ from discrete parts. Evidence: Thin-film failure often shows film delamination, open traces, substrate cracks or solder joint fatigue rather than bulk resistor burning. Explanation: Symptoms vary—stable drift suggests film degradation, sudden opens indicate trace break or solder fracture, and intermittent behaviour typically points to package stress or solder fatigue.

2 — Safety, Tools & Test Setup (data & preparation)

2.1 Required equipment and bench setup

Point: Use precision instruments and ESD controls. Evidence: Recommended gear: 4½–5½ digit multimeter, LCR meter, precision source‑meter, inspection loupe or microscope, hot‑air station, optional thermal chamber, ESD mat and wrist strap, and a non‑heating test fixture. Explanation: Instrument resolution and stable grounding are essential for reliable thin‑film resistor testing and to avoid introducing thermal or electrostatic faults.

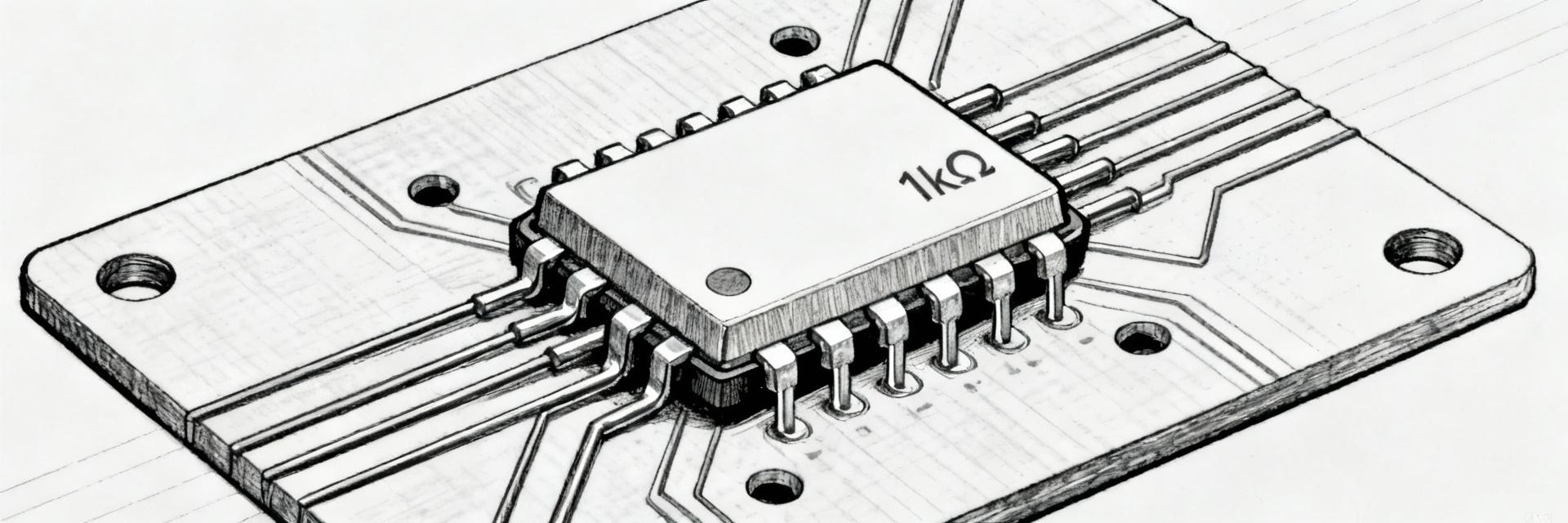

2.2 Recommended test-fixture wiring and reference measurements

Point: Implement a non‑invasive fixture and record ambient references. Evidence: Use a 16‑pin breakout with spring probes placed to avoid heating leads; perform zero‑offset and open‑circuit checks before measurements and log ambient temperature and humidity plus instrument IDs. Explanation: Reference measurements and consistent probe placement reduce measurement variance and support traceable pass/fail decisions during testing.

3 — Diagnostic Testing Workflow (data analysis + method)

3.1 Rapid screening tests (fast triage)

Point: Rapidly triage to separate obviously failed units. Evidence: Run continuity/open checks, a quick resistance scan with a multi‑channel meter, and a visual checklist for cracks, solder bridges, or corrosion. Explanation: Set pass/fail thresholds (e.g., open = OL; within ±0.1% for obvious good units at ambient) to flag units for detailed testing, saving bench time.

3.2 Detailed electrical testing procedures

Point: Follow precision measurement steps. Evidence: Use four‑wire measurements for single‑element verification, allow settling time, average multiple readings, run a TCR delta method (measure at two controlled temperatures) and perform a power/stress soak using a controlled current profile while monitoring drift. Explanation: Document ±0.1% at 25°C as a baseline, specify TCR acceptance per datasheet, and watch for monotonic drift during power stress that indicates film degradation.

4 — Repair & Rework Procedures (method guide)

4.1 Common field repairs (solder joints, leads, package-level fixes)

Point: Focus on the least invasive fixes first. Evidence: Typical successful repairs are reflowing suspect solder joints, replacing bent leads or reseating sockets; use controlled reflow temperatures and short dwell times while observing ESD precautions. Explanation: Reflow at conservative temperatures with preheat limits reduces risk of film damage; if solder fatigue is root cause, rework plus mechanical stress relief often restores reliable contact.

4.2 When to replace vs. attempt repair

Point: Use a clear decision tree. Evidence: If an element is open, non‑recoverable by thermal reflow and shows substrate cracking on inspection, recommend replacement; marginal tolerance or slight drift may merit repair if time/cost justified. Explanation: Consider repair time, failure recurrence risk, and traceability; if multiple adjacent elements show degradation, full network replacement is more reliable.

5 — Failure Case Studies & Troubleshooting Examples (case/display)

5.1 Example 1: Intermittent resistance under thermal cycling

Point: Intermittent drift usually indicates mechanical or solder fatigue. Evidence: Symptom: resistance toggles during thermal cycling; diagnostics revealed microfracture at lead frame. Explanation: Corrective action: controlled reflow and reinforcement of the lead or socket; verify with multiple thermal cycles and resistance logging to confirm stability.

5.2 Example 2: High TCR/drift after power stress

Point: Elevated TCR points to film degradation. Evidence: After a power soak test the element showed progressive upward drift and failed TCR spot checks. Explanation: Isolate by single‑element four‑wire checks; if drift persists, discard the network—film degradation is not reliably repairable and replacement prevents recurrence.

6 — Maintenance, QA Checklist & Documentation (action recommendations)

6.1 Final verification & acceptance tests

Point: Define a minimum QA suite. Evidence: Required checks: resistance tolerance at 25°C, TCR spot check, insulation/isolation verification, visual inspection, and a short burn‑in profile with logged measurements. Explanation: Use explicit pass/fail criteria (e.g., ±0.1% tolerance, TCR within datasheet ppm/°C) and store logs with instrument IDs for traceability.

6.2 Preventive handling and storage best practices

Point: Prevent repeat failures through handling rules. Evidence: Enforce ESD procedures, store units in controlled humidity/temperature, mark reworked parts and limit shelf‑life for reworked stocks. Explanation: Update BOM and test instructions to capture recurrent failure modes, reducing future returns and improving yield.

Summary

Point: Apply a consistent workflow for rapid, accurate fixes. Evidence: Initial triage, precision testing, targeted rework and a minimum QA suite restore most units. Explanation: For repeatability, adopt a test‑jig template and unified logging format so technicians can reduce diagnosis time and record repair outcomes for continuous improvement; use TDP16035002AUF reference data during testing.

Key Summary

- Follow a staged testing flow: visual inspection, quick resistance scan, then precision four‑wire and TCR tests to isolate failures in thin‑film resistor networks and capture measurable evidence for repair decisions.

- Use appropriate tools: 4½–5½ digit DMM, source‑meter, LCR, microscope, ESD controls and a non‑invasive 16‑pin fixture; log ambient conditions and instrument IDs for traceability.

- Repair only when root cause is mechanical or solder‑related; replace when an element shows irreversible film degradation or multiple adjacent elements fail tolerances to avoid recurring failures.

Frequently Asked Questions

How should I scope a basic testing routine for TDP16035002AUF?

Start with a rapid visual and continuity check, then a multi‑channel resistance scan; follow with four‑wire precision readings for any marginal elements, and a short TCR spot check between two controlled temperatures. Document instrument IDs and ambient conditions to ensure repeatable results and defensible pass/fail calls.

What pass/fail thresholds are practical for thin-film resistor testing?

Use ±0.1% at 25°C for critical applications as an initial acceptance window, and verify TCR against datasheet ppm/°C limits using delta temperature measurements. Consider element open or OL as immediate fail; any monotonic drift during power soak exceeding tolerance should mandate replacement.

Can most solder joint issues be repaired without damaging the thin-film resistor?

Yes—if reflow is done with conservative preheat and peak temperatures and short dwell times while monitoring ESD precautions. Avoid excessive local heating; if visual or microscopy inspection shows substrate cracking or delamination, do not attempt further thermal rework—replace the network.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- TOMC16031000FT5 Datasheet: Key Specs & Performance

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606