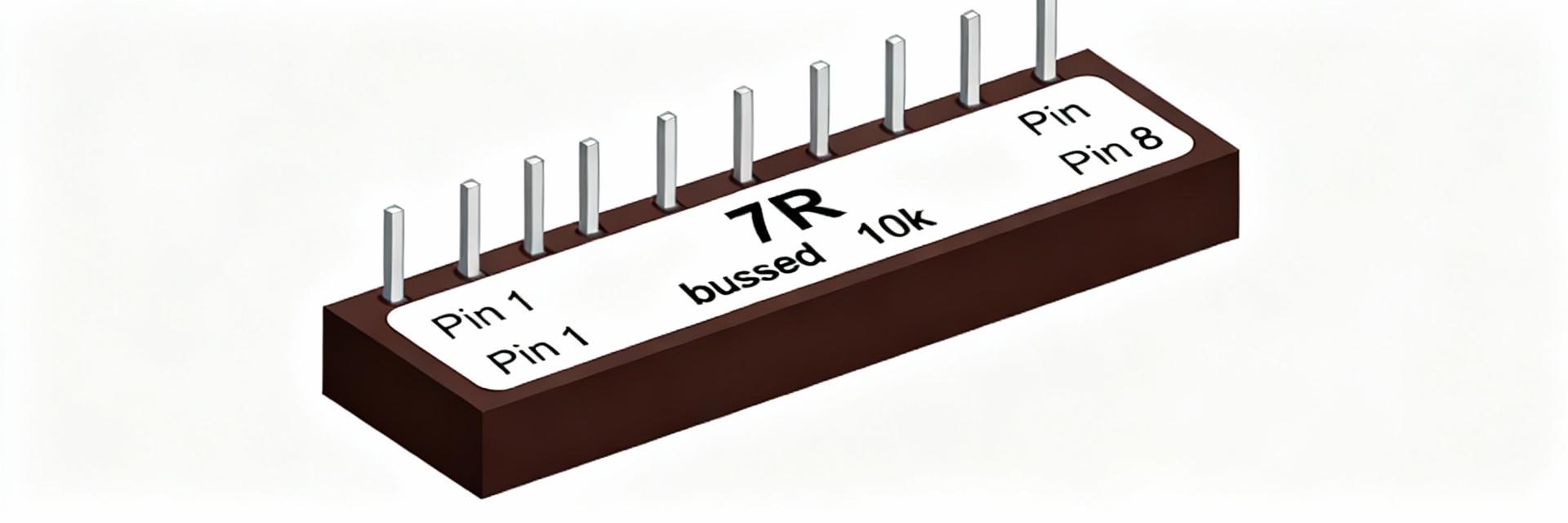

Hook — The MSP08A0110K0GDA is commonly listed as a 7-element bussed resistor network in an 8‑pin SIP with a typical nominal resistance of 10 kΩ and published temperature coefficients often near 100 ppm/°C; designers should confirm exact values in the official datasheet before final selection. This quick report summarizes datasheet items and practical implications for engineering and purchasing decisions.

Purpose — This fast reference condenses the MSP08A0110K0GDA datasheet essentials and specs so engineers and procurement teams can rapidly evaluate fit, design-in risks, and substitute candidates. It prioritizes electrical limits, mechanical footprint, test guidance, and sourcing checks needed to move from datasheet reading to BOM inclusion.

1 — Quick ID & Overview (background introduction)

1.1 — Part summary and common variants

PointThe MSP08A0110K0GDA is a molded single‑in‑line package housing seven resistive elements arranged in a bussed topology; datasheet excerpts report 8 pins, matched elements, and options for tolerance and TCR. EvidenceTypical listings show 10 kΩ nominal and tolerance options; variants trade tolerance or power rating for size. ExplanationChoose the exact suffix when tolerance, power per element, or TCR drive the design.

1.2 — Typical applications

PointCommon uses leverage the compact, matched, bussed format. EvidenceEngineers use these arrays where space, matching, and multiple pull resistors are required. ExplanationTypical uses includePull‑up/pull‑down resistor arrays for logic rails — compact matched values and simplified routing.

Bus termination in low‑speed lines — bussed common simplifies multi‑line terminations.

Sensor interface resistor networks — matched elements reduce offset and drift between channels.

Compact, space‑constrained PCBs — SIP footprint packs multiple resistors in one component.

2 — Complete Electrical Specs & Ratings (data analysis)

2.1 — Key electrical parameters to extract from the datasheet

PointA checklist ensures no critical spec is missed. EvidenceDatasheets list resistance, tolerance, TCR, power per element, max working voltage, insulation/resistance to substrate, and operating temperature range. ExplanationBefore approval, pull exact numeric values for each item and flag discrepancies across distributor listings and revisions.

Resistance value(s) and configuration (bussed vs isolated)

Tolerance classes (%), available options

Temperature coefficient (ppm/°C)

Power dissipation per element (mW or W) and derating rules

Maximum working/continuous voltage and insulation to substrate

Operating temperature range and storage limits

2.2 — Typical performance examples & how to interpret them

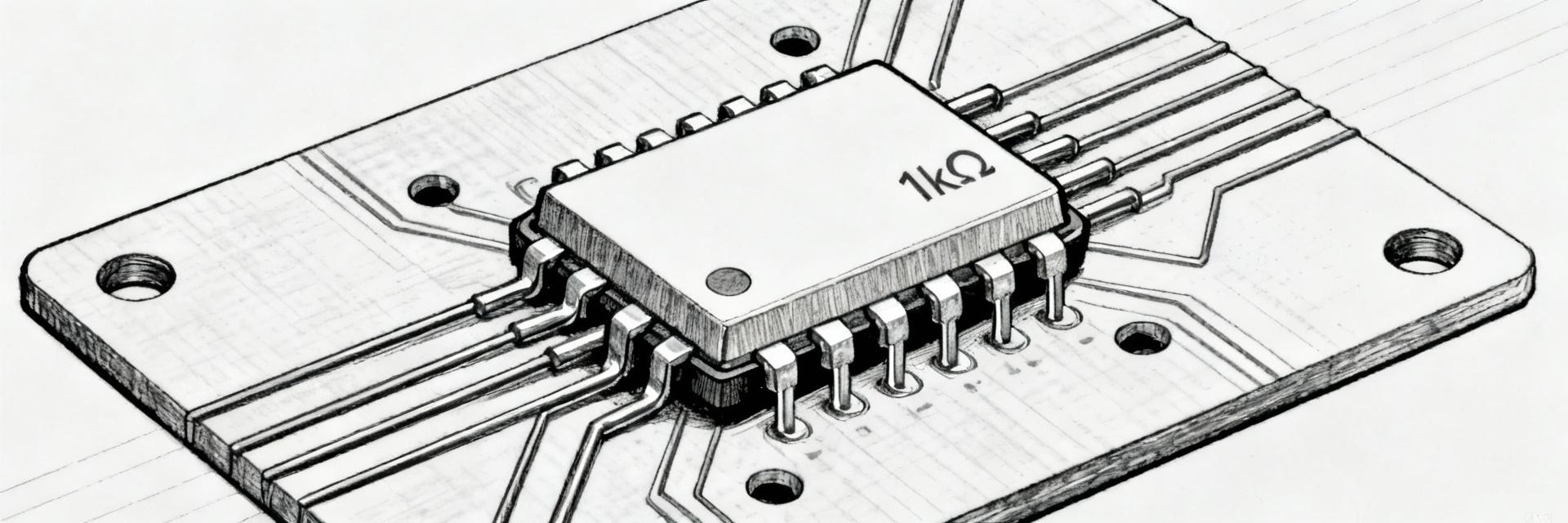

PointTranslate TCR and tolerance into expected in‑circuit behavior. EvidenceFor a 10 kΩ element with 100 ppm/°C over −40 to +85 °C (ΔT = 125 °C), the fractional change is 0.0125, i.e., ~1.25% drift or ~125 Ω. ExplanationUse this to budget worst‑case drift; similarly compute power using P = V²/R to check element limits in bussed versus isolated wiring.

3 — Pinout, Package & Mechanical Data (data analysis / method)

3.1 — Pin numbering, circuit diagram & footprint notes

PointAccurate pin documentation prevents assembly errors. EvidenceThe datasheet figure defines which pins form the common bus and which are individual terminals; footprints use standard SIP pitch. ExplanationRecreate the datasheet diagram in CAD, verify pin pitch and body length, and include a silkscreen reference; avoid guessing common pin location — confirm from the official drawing.

3.2 — Mechanical, thermal and packaging details to verify

PointMechanical checks affect PCB yield and thermal behavior. EvidenceImportant specs include package length/width/height, lead finish, recommended land pattern, and packaging type (tube or reel). ExplanationVerify lead finish for solderability, follow recommended land pattern, and apply thermal derating if the per‑element power is limited by package heat sinking.

4 — Design, Testing & Integration Guidance (method / practical)

4.1 — Design checklist for engineers

PointA short integration checklist reduces rework. EvidenceActions to take include confirming electrical ratings, checking power dissipation per element, planning thermal reliefs, and specifying tolerance in the BOM. ExplanationExample — if a termination sees 5 V across 10 kΩ, P = V²/R = 2.5 mW; this is well below common per‑element ratings, but parallel or bussed uses can concentrate power and require derating.

4.2 — Test and validation recommendations

PointPractical tests catch subtle failures early. EvidenceRecommended bench tests include room‑temperature resistance verification, controlled temperature sweeps to measure drift, power cycling, and long‑term drift characterization for matched networks. ExplanationWatch for common failure modes such as element overpower, solder fatigue, and package cracking; document test conditions to match intended field use.

5 — Sourcing, Cross-References & BOM Tips (case study / action)

5.1 — How to verify you have the correct datasheet and part variant

PointFull part‑number matching avoids costly mistakes. EvidenceConfirm the complete PN suffix, package type, element count/configuration, resistance value, tolerance, and power rating against the datasheet revision. ExplanationUse a long‑tail search phrase such as "MSP08A0110K0GDA resistor network datasheet download" to locate the official datasheet PDF and compare pin count and dimensional drawing before ordering.

5.2 — Alternatives, substitutions & procurement tips

PointSubstitutes must match electrical and mechanical constraints. EvidenceMatch package, element count and topology (bussed vs isolated), resistance/tolerance, TCR and power per element; also check MOQ, lead time, packaging, and lifecycle status. ExplanationCreate a procurement checklist that includes lifecycle status and packaging type to avoid end‑of‑life surprises and requalification work.

Summary (conclusion & quick-spec snapshot)

Recap — The MSP08A0110K0GDA is typically a 7‑element, 8‑pin bussed resistor network with a common nominal value near 10 kΩ; designers must confirm the exact variant and datasheet revision before final selection. Three critical checks are power per element, TCR (ppm/°C) and package/footprint to ensure thermal and assembly compatibility. Download the datasheet and run the checklist prior to BOM freeze.

MSP08A0110K0GDA typical identity8‑pin SIP, 7 bussed resistors, ~10 kΩ nominal; verify in datasheet.

Electrical prioritiesconfirm tolerance, TCR (ppm/°C), power per element and max working voltage before design signoff.

Mechanical prioritiesconfirm pin pitch, body length, lead finish and recommended land pattern to reduce PCB rework.

5 — 常见问题解答 (FAQ)

What are the MSP08A0110K0GDA datasheet key electrical ratings?

Answer — Key electrical ratings to extract from the datasheet include each element's nominal resistance, tolerance class, temperature coefficient in ppm/°C, power dissipation per element, maximum working voltage, insulation resistance to substrate, and operating temperature range. Verify these against the exact part suffix and datasheet revision before approving the component for production.

How should MSP08A0110K0GDA specs be interpreted for temperature drift?

Answer — Use the TCR value to compute worst‑case driftfractional change = TCR(ppm/°C) × ΔT. For example, 100 ppm/°C over a 125 °C range yields ~1.25% change; for a 10 kΩ part this equals ~125 Ω shift. Budget this drift into accuracy margins and matching requirements.

What are acceptable substitutes for MSP08A0110K0GDA resistor network?

Answer — Acceptable substitutes must match topology (bussed vs isolated), element count, package (8‑SIP footprint), resistance and tolerance, TCR, and per‑element power. Also check footprint compatibility and thermal behavior; if any spec differs, re‑evaluate in‑circuit heating and matching implications before substituting on a production BOM.