-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

TOMC16031000FT5 Datasheet: Key Specs & Performance

The TOMC16031000FT5 from Vishay Thin Film is specified for operation across −55 °C to +125 °C, making it a candidate for precision instrumentation in harsh environments. This summary distills the official datasheet into key electrical, thermal, and reliability parameters engineers need for selection and integration, referencing the vendor datasheet as the source of truth.

1 — Product Overview & Identification (Background)

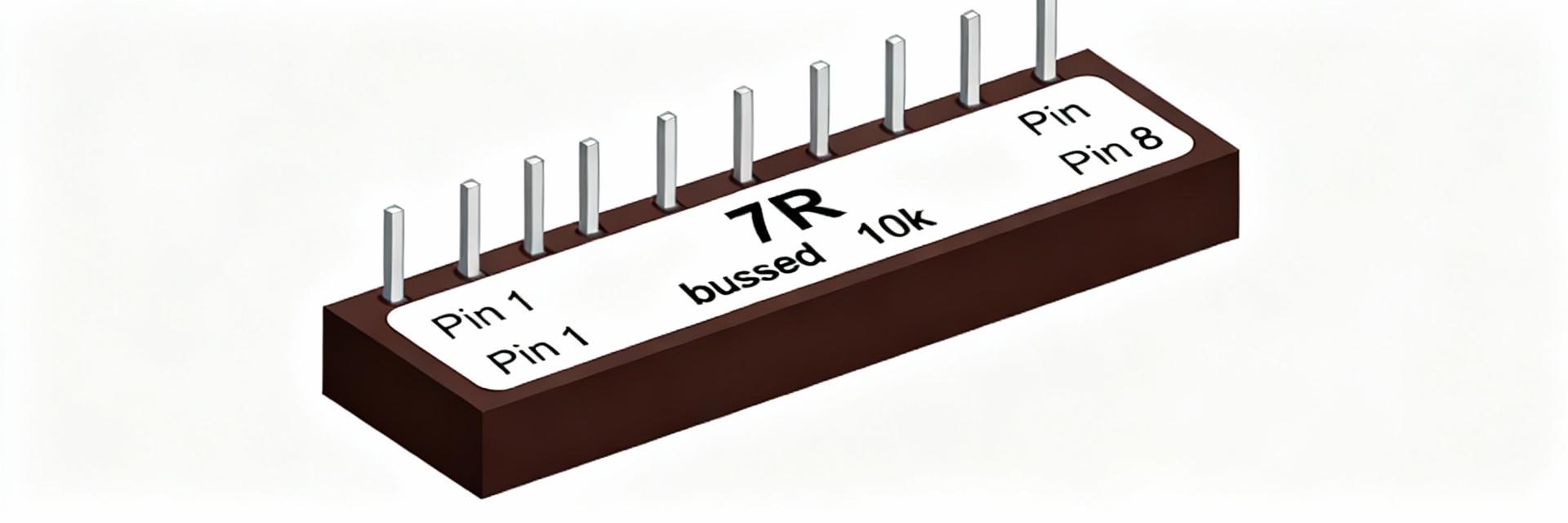

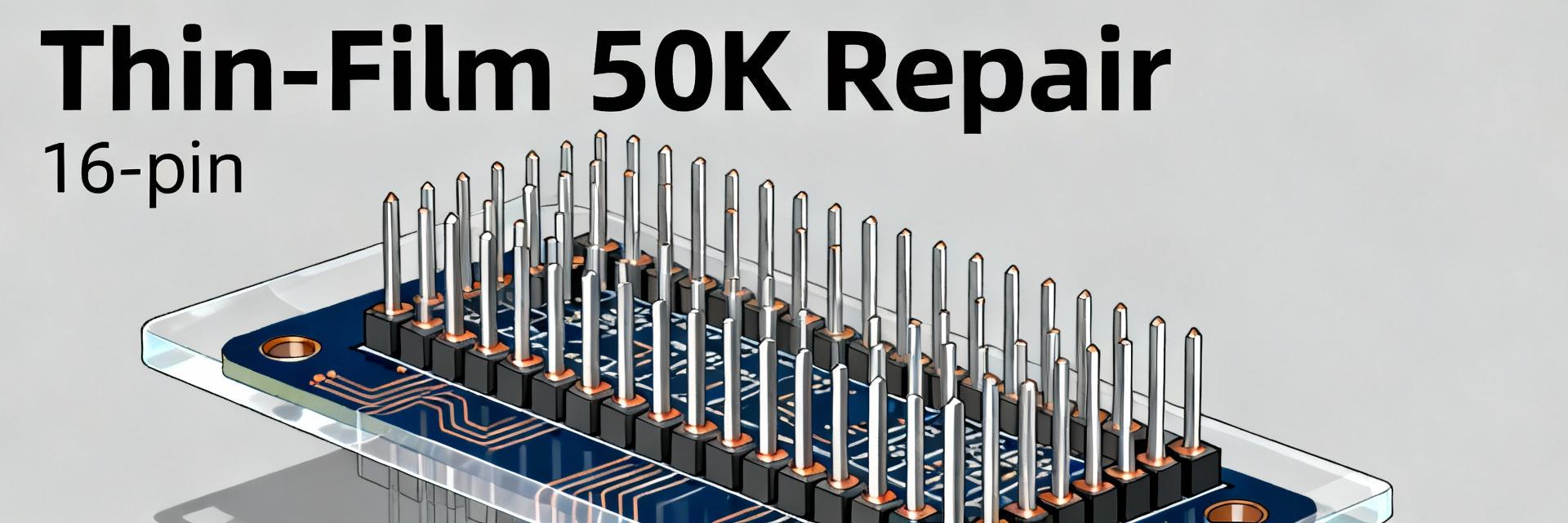

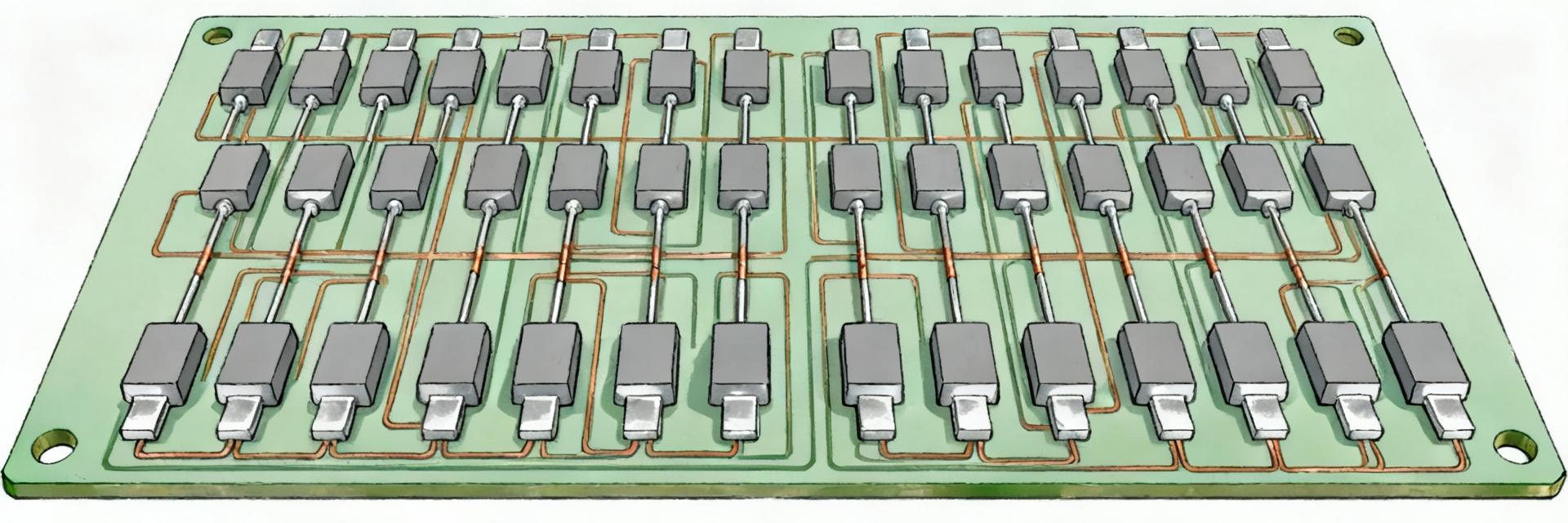

Point: The TOMC16031000FT5 is a molded thin-film resistor network in a small dual-in-line package used where matched resistances and tight stability are required. Evidence: The vendor listing notes a molded package with a typical footprint length 11.176 mm and width 5.59 mm, and a part-number format that embeds series, resistance value and tolerance. Explanation: Understanding the package and code lets designers confirm footprint fit, pinout, and assembly clearance before PCB layout.

Part-number anatomy & package description

Point: Decode the part number by series, nominal resistance and option suffix. Evidence: The TOMC prefix identifies the series; the embedded numeric block indicates the nominal resistance for that SKU; option suffixes denote tolerance and packaging variant. Explanation: Designers should map the SKU to the mechanical drawing in the official datasheet to verify pad geometry, body length 11.176 mm and width 5.59 mm, and pin spacing before finalizing the footprint.

Where to find the official datasheet and ordering codes

Point: Always retrieve the manufacturer PDF to confirm ordering codes and packaging. Evidence: The official product datasheet lists ordering codes, available packaging options (tray, tape-and-reel), and any minimum order quantities or lead-time notes. Explanation: Procurement should request the exact datasheet PDF from the manufacturer product page and record the ordering code and packaging type on purchase orders to avoid mismatched variants.

2 — Electrical Specifications Deep-Dive (Data analysis)

Point: Electrical specs determine suitability for precision applications. Evidence: The datasheet lists nominal resistance, available tolerances and the temperature coefficient of resistance (TCR) for each option. Explanation: For circuit design extract the nominal R and the TCR (ppm/°C) to calculate drift across operating range and choose the tolerance class that meets precision requirements.

Resistance values, tolerance & temperature coefficient (TCR)

Point: Select the correct resistance and tolerance variant for required accuracy. Evidence: The series offers discrete nominal resistances and multiple tolerance/TCR options; specific SKUs correspond to fixed resistance values. Explanation: Build a compact selector table during design (nominal resistance | tolerance | TCR | typical application) using the datasheet columns so that the chosen part meets both DC accuracy and temperature stability needs in the final system.

Power rating, maximum voltage & noise/voltage coefficients

Point: Power handling and voltage limits define safe operating area. Evidence: The datasheet provides dissipation per resistor, maximum working voltage and any voltage coefficient or excess noise specifications. Explanation: Use the datasheet derating curve to calculate allowable power at elevated ambient temperature; perform a simple PCB-level power budget example treating the resistor as the thermal node and applying the manufacturer derating rule.

3 — Performance & Thermal Reliability (Data analysis)

Point: Thermal behavior governs long-term stability under load. Evidence: The datasheet specifies operating temperature −55 °C to +125 °C and includes thermal impedance and derating curves. Explanation: Translate the derating curve into a temperature vs allowable power chart and apply TCR to estimate resistance drift across the worst-case ambient for the product application.

Operating temperature, thermal derating & thermal impedance

Point: Apply thermal derating early in design to avoid overstress. Evidence: The official specification shows the −55 °C to +125 °C operating window and thermal-impedance guidance for junction-to-ambient calculation. Explanation: Calculate worst-case power per resistor at the highest ambient and confirm the resistor is operated below the derated limit to prevent accelerated drift or failure.

Environmental & reliability testing (shock, vibration, humidity, aging)

Point: Reliability tests validate suitability for high-reliability programs. Evidence: The datasheet summarizes standard tests such as humidity, thermal cycling, mechanical shock, vibration and load life. Explanation: For qualification, request test reports for the specific lot or request extended screening (e.g., additional thermal cycles or longer load life) and interpret pass/fail against the published limits to estimate field life and MTBF implications.

4 — Integration & Application Guidelines (Method guide)

Point: Mechanical and process choices affect in-circuit performance. Evidence: Manufacturer mechanical drawings and recommended reflow profiles are published in the datasheet. Explanation: Use a footprint checklist—verify pad geometry, solder fillet area and spacing against the drawing; follow the recommended reflow profile and include thermal reliefs to minimize solder-induced stress.

PCB layout, soldering, and mechanical mounting best practices

Point: Proper pad design and soldering prevent stress and thermal overstress. Evidence: The datasheet provides pad recommendations and soldering cautions. Explanation: Implement recommended pad geometry, keep symmetric copper pour to maintain thermal balance, and avoid routing high-current traces adjacent to precision networks; include a footprint verification checklist before fabrication.

Typical circuits & simulation notes

Point: Validate network behavior in simulation and on the bench. Evidence: Use nominal R and TCR from the datasheet as SPICE model parameters and include thermal coupling where available. Explanation: Example use cases include matched divider networks for ADC front-ends and Wheatstone bridges for sensors; validate models by measuring resistance at 25 °C and under expected thermal loading to confirm simulated behavior.

5 — Procurement, Testing & Compliance Checklist (Action suggestions)

Point: A disciplined procurement and incoming test flow prevents field issues. Evidence: The datasheet plus manufacturer ordering codes support correct sourcing and traceability. Explanation: Establish sourcing from authorized distribution channels, record the datasheet revision and ordering code, and plan incoming inspection and sample life testing aligned with the datasheet limits before production acceptance.

Sourcing strategy, alternates & pricing considerations

Point: Match technical requirements and supply constraints. Evidence: The datasheet and product codes indicate available packaging and variants that affect price per unit. Explanation: When searching alternates match package, TCR, tolerance and environmental rating; choose tray or reel packaging based on assembly throughput and negotiate MOQ to optimize unit cost.

Recommended bench tests & pass/fail criteria before deployment

Point: Practical tests confirm conformance to datasheet specs. Evidence: Essential checks include DC resistance at 25 °C, TCR spot-check across temperature, power/derating verification and dimensional confirmation to mechanical drawing. Explanation: Define pass/fail limits tied to datasheet tolerances (e.g., resistance within specified tolerance, drift within TCR × ΔT) and document test equipment and settings for traceability.

Summary

- The TOMC16031000FT5 offers precision thin-film network performance with an operating range of −55 °C to +125 °C; consult the TOMC16031000FT5 datasheet for exact tolerance and TCR selections.

- Key design checks: verify mechanical footprint (length 11.176 mm, width 5.59 mm), apply thermal derating, and include TCR in drift calculations for precision circuits.

- Procurement and test steps: confirm ordering code and packaging, perform incoming resistance and TCR spot checks, and run a power-derating verification before assembly.

Frequently Asked Questions

What are the essential datasheet items to verify for resistor network selection?

Check nominal resistance options, tolerance, TCR (ppm/°C), maximum working voltage, power dissipation per element and the mechanical footprint. Also confirm the operating temperature range and any environmental test data to ensure the part meets your application’s thermal and reliability demands.

How should I validate thermal derating on the bench?

Measure resistance and temperature rise under controlled power dissipation using a thermal chamber or fixture. Compare measured allowable power at elevated ambient against the datasheet derating curve; a 10–20% safety margin beyond datasheet limits is common for critical designs.

What incoming inspection tests are recommended before accepting a reel or tray of networks?

Perform DC resistance at 25 °C on a statistically significant sample, TCR spot-check across the expected operating range, visual/mechanical dimension verification against the drawing, and a short power/load life test on sample units to confirm stability under load.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- TOMC16031000FT5 Datasheet: Key Specs & Performance

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606