-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

NOMC16031003FT5 Datasheet Deep Dive: Key Specs & Tests

The NOMC16031003FT5 delivers a 25 ppm/°C temperature coefficient and an operating range of −55°C to +125°C, making it suitable for high-reliability boards. This article is a focused walk-through of the NOMC16031003FT5 datasheet, highlighting the critical specs engineers must watch and practical bench and production tests to validate performance and reliability against those published values.

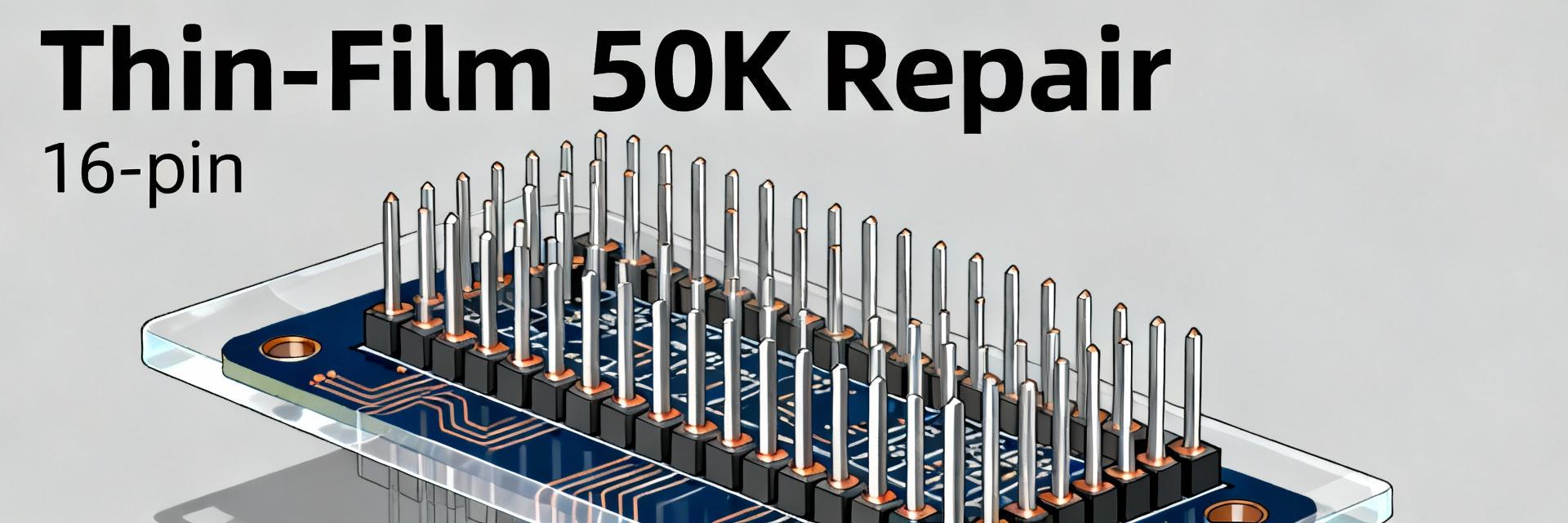

What is the NOMC16031003FT5? Quick part overview (Background)

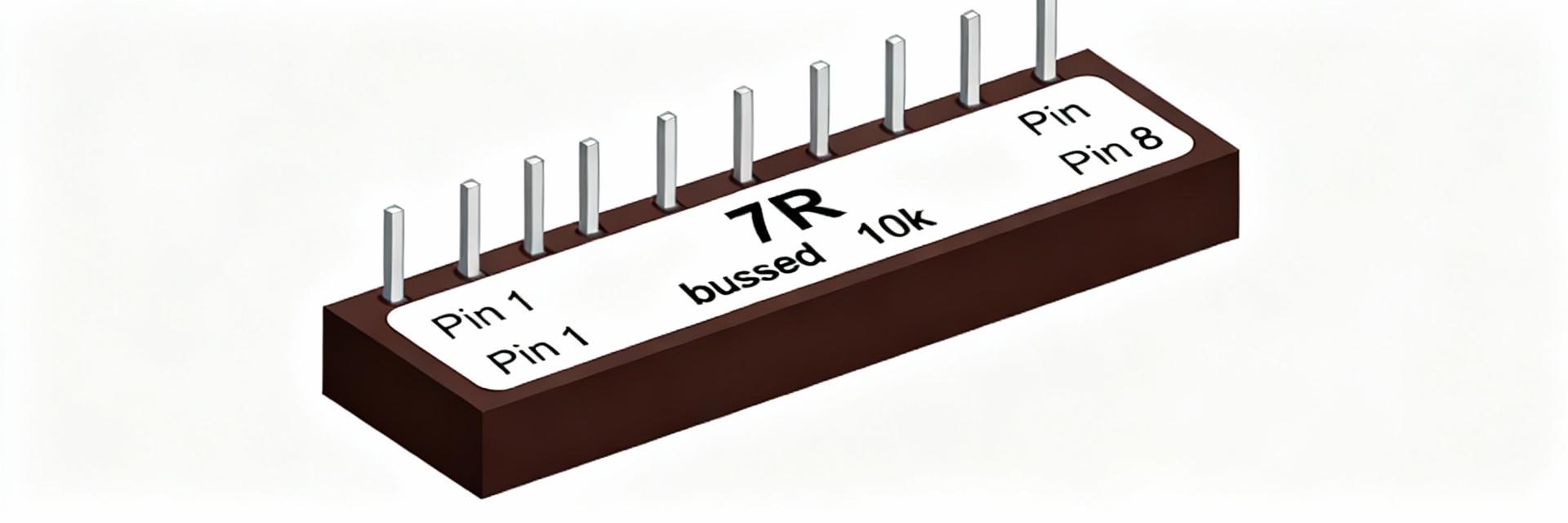

Point: The part is an isolated thin-film resistor array offered in a 16-pin SOIC outline intended for precision, space-efficient networks. Evidence: The package hosts eight discrete resistors in a compact footprint suitable for matched networks and pull-up/pull-down arrays. Explanation: Designers leverage the compact array to save board area and ensure matched thermal and tracking behavior when implementing dividers, sensor front-ends, or level-shifting networks.

Part family & functional description

Point: Functionally this PN is an eight-element resistor network with isolated terminations for independent circuit use. Evidence: Typical use cases include matched resistor ladders, sensor conditioning, and pull‑ups where element-to-element tracking and low TCR are important. Explanation: The isolated array topology minimizes crosstalk between elements while preserving consistent thermal behavior across matched channels, simplifying layout and calibration in precision analog and mixed-signal systems.

Typical package & pinout at a glance

Point: The device arrives in a 16-pin SOIC (50 mil pitch) shell with standard pin mapping for eight isolated resistors. Evidence: Package outline and recommended land pattern are compact with no exposed thermal pad; pin assignment places each resistor terminal on opposite sides for convenient routing. Explanation: Verify footprint pitch, pad-to-pad spacing and silkscreen orientation during library creation to avoid rotated or mirrored land patterns that cause assembly defects.

- Footprint checks: pitch, pad size, solder mask expansion, and silkscreen polarity.

- DRC checklist: keepout for thermal relief, ensure solder fillet accessibility, and confirm 50 mil pitch alignment.

Key specs from the datasheet — electrical, mechanical & thermal (Data analysis)

Point: The datasheet lists electrical, mechanical and thermal limits that govern selection and derating. Evidence: Core values include nominal resistance, tolerance variants, TCR, power per element, tracking, and isolation. Explanation: Extracting these verbatim and translating them into board-level implications prevents surprise failures and informs test limits during component qualification and production acceptance.

Electrical specifications to prioritize

| Parameter | Typical / Spec |

|---|---|

| Nominal resistance | 100 kΩ |

| Tolerance | ±1% (other variants ±0.1%) |

| Power per element | 100 mW |

| Resistor matching / tracking | ±0.025% |

| TCR | 25 ppm/°C |

| Isolation | High; suitable for independent circuits |

Explanation: Resistance value and tolerance determine divider accuracy; matching/ tracking controls relative error in multi-resistor topologies; TCR affects gain and offset over temperature swings; per-element power limits determine derating and layout thermal management. For example, a 25 ppm/°C TCR across a 70°C change yields ≈0.175% drift — critical for precision amplifiers.

Mechanical & thermal limits from the datasheet

Point: Mechanical and thermal specs set allowable environments and assembly processes. Evidence: Operating range extends to −55°C to +125°C, storage and soldering profiles listed, and maximum package dimensions defined. Explanation: Use the reflow profile for process windows, apply derating rules to power dissipation, and place thermal vias or copper pours if multiple adjacent elements dissipate heat to avoid localized derating beyond published per-element power.

| Item | Value / Note |

|---|---|

| Operating temperature | −55°C to +125°C |

| Reflow | Standard Pb-free profile; follow peak temp and time limits |

| Package dims | 16-SOIC outline; confirm in layout library |

Performance tests & validation: what to bench and inspect for the NOMC16031003FT5 (Data analysis / Method)

Point: A focused test matrix ensures parts meet datasheet claims before acceptance. Evidence: Recommended equipment includes a precision LCR meter, 4-wire Kelvin fixtures, thermal chamber, and power source with current limiting. Explanation: Combining electrical verification with thermal testing reproduces real-world stresses and populates qualification records for FMEA and component sign-off.

Essential lab tests (must-run)

- Continuity & isolation: 4-wire resistance measurements of each element; confirm isolation between elements within specified leakage limits.

- Tolerance check: batch sampling against nominal 100 kΩ with acceptance ± specified tolerance.

- TCR verification: hot/cold soak method with thermal chamber, logging ppm/°C against baseline.

- Power dissipation test: incremental power sweep to verify temperature rise and immediate drift.

Actionable: Log all measurements with time and serial references; set pass/fail margins slightly inside datasheet limits to build margin for aging and assembly variance.

Reliability & stress tests (production / qualification)

Point: Long-term and stress testing qualify parts for intended shelf and field life. Evidence: Typical plans include thermal cycling, solderability checks per reflow profile, humidity soak, and long-term drift monitoring at elevated temperature. Explanation: Define sample sizes per AEC‑Q style guidance or internal QA norms, record drift trends at regular intervals, and update the FMEA with observed failure modes such as open elements or irreversible drift.

Design integration guide: footprint, BOM, derating & matching tips (Method / Action)

Point: Integration guidance reduces rework and improves yield. Evidence: Keep matched nets symmetrical, isolate routing that may induce thermal gradients, and follow recommended land pattern tolerances. Explanation: Small layout choices markedly affect tracking; a symmetric layout preserves matched thermal conditions and minimizes relative drift between paired elements in precision circuits.

PCB layout & footprint best practices

- Route matched pairs symmetrically and avoid heavy copper runs near only one element.

- Use thermal vias beneath nearby power dissipation areas if multiple elements will share load.

- DRC rules: enforce pad-to-pad clearance consistent with 50 mil pitch and allow fillet expansion.

BOM, assembly and derating guidance

Point: BOM clarity and derating safeguard procurement and assembly. Evidence: List full PN with suffixes for tolerance/TCR on BOM; include solder paste stencil notes and storage humidity controls. Explanation: A sample BOM line should include the exact part number, tolerance, and TCR suffixes; derate continuous power to 60–70% of per-element rating in dense arrays to ensure long-term stability.

Sourcing, equivalents & troubleshooting checklist (Case study / Action)

Point: Procurement and replacement strategy depend on matching electrical and thermal parameters. Evidence: Verify datasheet PDFs, manufacturer ident codes, and authorized distribution channels during purchase. Explanation: When substituting, match resistance, tolerance, TCR, topology and package; for troubleshooting, isolate failures to open resistors, drift beyond acceptance, or solder joint defects and document findings for QA closure.

Where to buy and how to verify authenticity

Actionable: Purchase through authorized distributors or direct manufacturer channels; confirm datasheet PDFs, part marking, and traceability. Red flags include large price discrepancies, missing datasheets, or inconsistent markings. Maintain PO records and lot traceability to speed field failure analysis and returns if defects surface.

Closest equivalents and substitution strategy

Actionable: Match key parameters—nominal resistance, tolerance, TCR, array topology and package—when qualifying equivalents. For quick qualification, run a reduced set of bench tests (resistance, TCR spot check, solderability) and a small thermal cycle sample to validate cross-vendor behavior before full substitution.

Summary

The NOMC16031003FT5 is a thin-film, isolated eight-element resistor array in a 16-SOIC package optimized for precision and high-temperature applications; designers must verify TCR, tolerance and per-element power rating and run bench and reliability tests prior to production. Use the datasheet values as the baseline for layout, derating and QA limits and document test results for component qualification and FMEA records.

- Confirm electricals: measure each element for nominal value, tolerance and matching to ensure divider accuracy and low differential drift in precision circuits.

- Thermal planning: apply derating rules and layout symmetry to control temperature rise; validate with incremental power dissipation tests in the lab.

- Qualification: execute thermal cycling, solderability and long-term drift tests on representative samples and record outcomes for supplier acceptance.

SEO & writer notes (short checklist)

How should an engineer validate NOMC16031003FT5 performance in production?

Run sample-based electrical verification (4‑wire resistance and isolation), TCR spot checks using thermal chamber cycles, and a power dissipation ramp to confirm temperature rise. Log batch statistics and compare to datasheet tolerance bands; reject lots that exhibit systematic shift or excessive variance beyond acceptance criteria.

What are quick signs the NOMC16031003FT5 is failing in the field?

Look for open elements, resistors drifting outside tolerance, intermittent isolation loss, or solder joint fractures. Use portable LCR meters and visual inspection; correlate failures with thermal or mechanical stress history to determine root cause and corrective actions.

Which specs in the datasheet should purchasing reference on the BOM?

Include full part number with tolerance and TCR suffix, package outline, and key electrical values (resistance, tolerance, TCR, power per element) on the BOM. This ensures correct ordering, prevents substitution errors, and speeds qualification of equivalent parts when supply issues arise.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- TOMC16031000FT5 Datasheet: Key Specs & Performance

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606